SPLICED & VULCANIZED O-RINGS

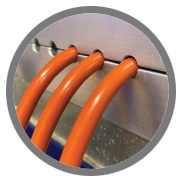

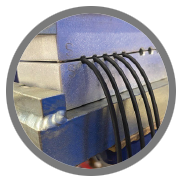

Spliced and vulcanized O-rings are made from the extruded cord stock that has been cut and

bonded together, as opposed to molded O-rings that have been compression or injection molded

as one piece. Vulcanized O-rings are an excellent choice for static sealing applications when

molded O-rings cannot be used due to large or non-standard dimensions. Vulcanized O-rings can

be made from a range of elastomers and in virtually any size or length.

|

|

|

|

|

Markets

|

|

Advantages of Spliced & Vulcanized O-Rings

CUSTOMIZATION

Continuous length cord is cut to a bespoke length and then hot vulcanized with a specialized bonding agent in a mold at a high temperature. This process forms the molecular bond necessary to ensure a strong joint.

PRODUCTION FLEXIBILITY

Spliced & vulcanized O-rings offer versatility in production, enabling Hercules OEM to quickly produce O-rings in various sizes and materials without the need for specialized tooling or unique molds.

INCREASED STRENGTH

The splicing & vulcanization process creates a strong bond between the ends of the cord, resulting in enhanced strength and durability. This makes spliced & vulcanized O-rings suitable for applications where a higher degree of resilience in a static application is required.

COST-EFFECTIVENESS

Spliced & vulcanized O-rings are created by joining the ends of extruded cords or extrusions, allowing for efficient production of O-rings in non-standard sizes. This can be a cost-effective solution for applications that require O-rings in unique dimensions or large sizes.

Additional Benefits of Vulcanized O-rings

- • Molds are not required resulting in huge cost savings

- • Shorter lead times

- • Short run cost savings vs long run

- • No upper diameter restrictions like molding

- • Tolerances can be tighter than molding tolerances

- • No parting lines

- • Custom and wandering groove shapes are possible

Materials

- • Silicone (VMQ)

- • FKM (Viton)

- • NBR (Buna)

- • EPDM

Cord Sizes

| • 0.070” • 0.103” • 0.139” • 0.210” • 0.250” |

• 0.275” • 0.312” • 0.375” • 0.500” • 0.625” |